The future is here: Plastic film that you can wear on your fingertips can diagnose medical conditions

12/10/2018 / By Edsel Cook

From the shores of Japan comes a film so thin, it could be folded a thousand times like a traditional samurai sword. And yet the folded plastic would still be slender enough to detect light, an article in Nanowerks reported.

The polymer material was developed by a research team from the RIKEN research institute. It has many potential uses, but for its debut, it demonstrated its ability to evaluate medical conditions when attached to the skin of a patient.

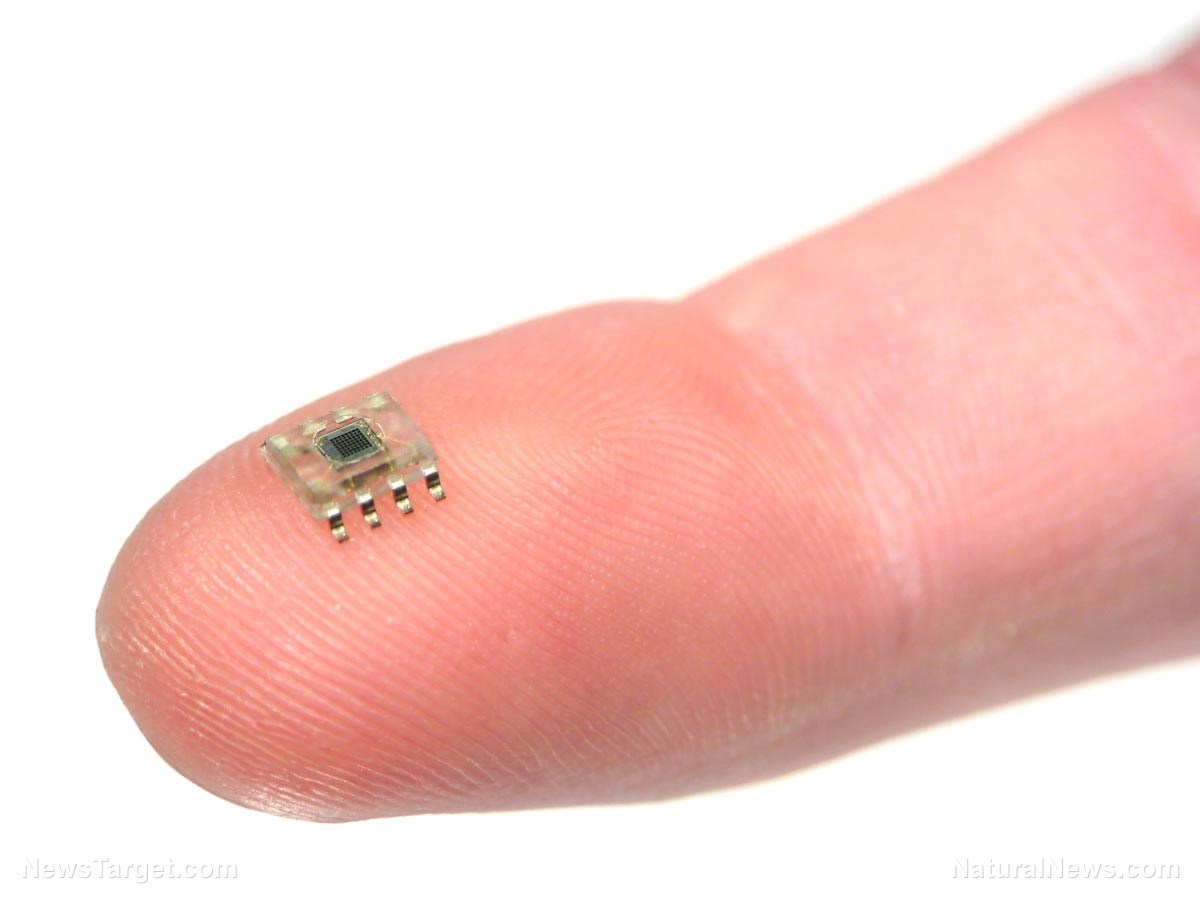

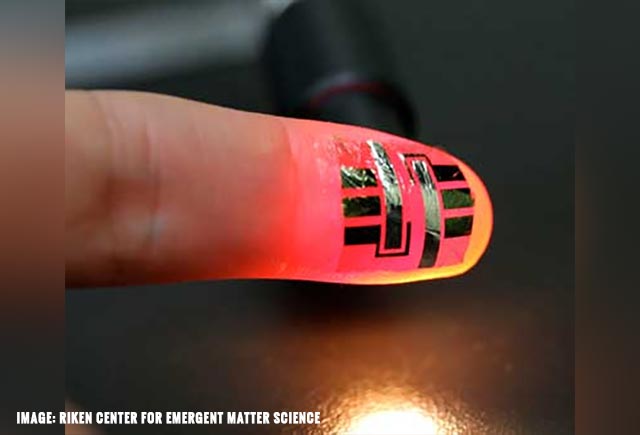

In the experiment, the plastic film was placed on the fingertip of a volunteer. It was able to measure the rate at which blood flowed through the skin with great accuracy.

Given the results of their study, the film is being touted as an excellent material for wearable medical devices. Such electronics would feel more pleasant for the wearer while also remaining effective at their role. (Related: New elastic “skin-tech” wearable display may revolutionize home healthcare.)

Developing a wearable sensor that is accurate and comfy on the skin

Conventional diagnostic sensors are usually made from silicon and other brittle materials. The frangibility of these materials made wearable electronics unpleasant for patients to bear for long.

The RIKEN researchers believe their new film can combine both comfort and functionality. Made up of organic molecules that can conduct electricity, the polymer possesses the flexibility to go with the flow of the wearer’s body.

Takao Someya and Kenjiro Fukuda lead the team. They have been working on polymer sensors that can pick up near-infrared light.

This form of radiation can pass through the skin, and light up the tissue found a few millimeters below. Near-infrared light is considered to be safe for humans.

Devices made with the earlier versions of the polymer could not read the signals fast enough. The reading speed slowed down even further whenever the material got stretched.

The RIKEN researchers identified two problems with the earlier device. The first was that the material did not conform well to the skin of users. The second was that the speed of the electron flow in the material slowed down due to structural stress.

Ultrathin diagnostic device can read vitals within milliseconds

They resolved this issue by massively reducing the thickness of the polymer near-infrared detector from 100 micrometers to just three micrometers. Using one type of polymer as the substrate, they laid out another layer of aromatic polymers that would serve as the ‘active layer’ that could detect near-infrared light.

The simple device was coated with yet another layer of the same polymer that formed the substrate. Finally, a final layer of nonstick material allowed the completed sensor to be extracted from a surface with ease.

During the validation test, the ultra-thin device withstood incredible amounts of stress. It could detect near-infrared light within a millisecond, even if it were squeezed into half its size.

Because it was so thin, the wearable electronic could cling to curved parts of the body like a second skin. This increased the accuracy of the readings, even when the patient was moving during the diagnosis period.

“Because we assembled the device components in a layer-by-layer fashion, we could locate them in a neutral plane where stress is minimal,” stated Sungjun Park, a RIKEN researcher who served as the first author of the study. “This maintains device performance under severe mechanical deformation.”

Park and his teammates plan to use the new plastic film in combination with organic LEDs, batteries, solar cells, and processes. They hope to create self-powered sensor systems that do not need an external source of power.

Check out Discoveries.news for more articles about wearable electronics.

Sources include:

Tagged Under: diagnostics, future technology, medical devices, polymers, sensors, wearable electronics